Sorting Nuts -private-

Our nuts sorting service ensures the quality and food safety of nuts. The machines on our sorting lines can get rid of nuts with any defects, foreign materials such as stones, branches and metal pieces, helping food companies ensure high standards of food hygiene.

Fuji Warehouse’s Nuts Sorting Line

In 2019, our nuts sorting factory has launched its operation at one of our bonded warehouses. We have introduced an air conditioner, LED lights, an air shower and dustproof wall & floor to maintain the hygienic environment.

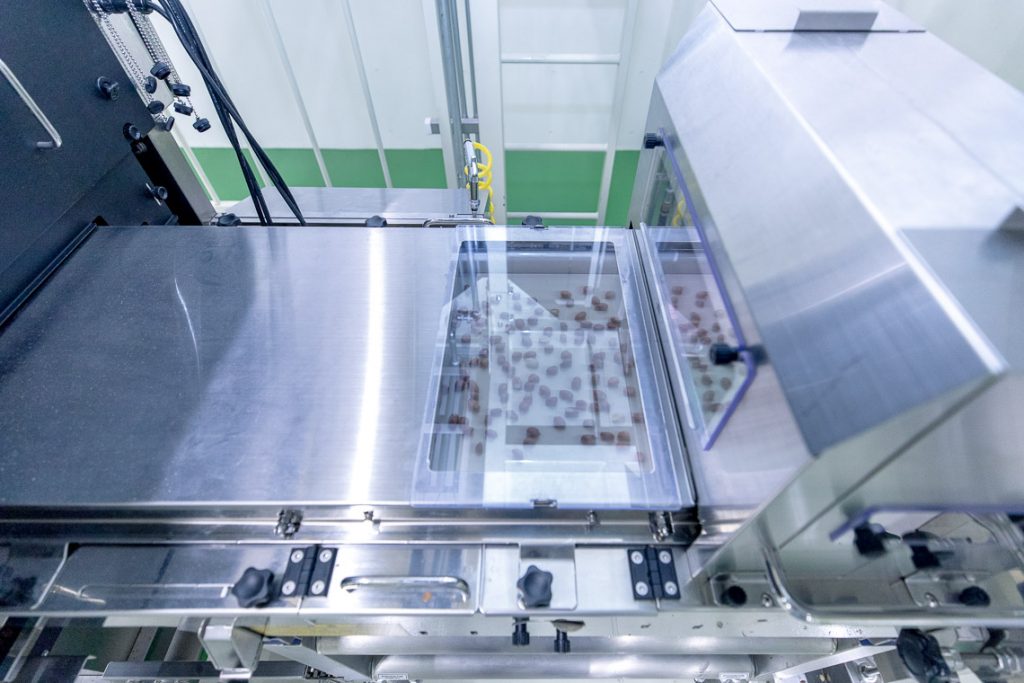

We offer two different lines for sorting nuts: Q Sorter Sorting Line and Selective Sorting Line. On the Q sorter sorting line, foreign materials and defective beans are removed by scanning by an infrared electronic sensor. On the selective sorting line, the main operation methods are color sorting and X-ray scanner to sort materials.

Our sorting services are flexible; depending on the condition of materials and the facilities you require, you can choose the best sorting process for your product; it is possible to use both and combine the hand-picking service as well for enhancing the quality of your product.

With our bonded warehouses, imported and exported products do not need to be delivered to another place for sorting, eliminating cost and saving time. Therefore, we are confident to provide a cost-effective, reliable and efficient food storage and nuts sorting service.

Our Sorting Processes

01 Q Sorter Sorting Line (For peanuts)

1:Hopper

A. Put ingredients into a stainless-steel hopper.

2:Vibration Screening Machine & Dust Collector

B. Small foreign materials such as shells and stones are removed by a vibration screening machine and a dust collector machine.

3:Q Sorter

C. Nuts with internal problems and foreign materials are detected by an infrared electronic sensor and are removed.

4 :Hand-picking & Magnet

D. Micro metal pieces are removed here using a strong magnet. Also, if necessary, our skilled staff visually inspect each piece of nut and remove any contaminants.

5:Weighing & Packing

E. Check the weight of each bag and seal it.

02 Selective Sorting Line (For peanuts)

1:Hopper

A. Put ingredients into a stainless-steel hopper.

2:Vibration Screening Machine, Dust Collector & Pneumatic Sorting Machine

B. Small foreign materials such as shells and stones are removed using three machines: a vibration screening machine, a dust collector machine and a pneumatic sorting machine.

3:Specific Weight Sorting Machine & 3 layer Vibration Screening Machine for sizing

C. A specific weight sorting machine selects non-standard beans and then they are sorted according to size by a 3-layer vibration screening machine.

4 :Color Sorting Machine

D. A color sorting machine scans the color of the surface of each nut and can remove moldy beans and discolored beans.

5:Piano Wire Sorting & Visual Inspection Conveyor

E. Half-cracked beans are removed by a piano line sorting machine. If necessary, then we can offer the hand-picked service by our skilled staff.

6:X-ray Scanner & Micro-metal Detector

F. Hard foreign materials such as metal piece, glass and rubber are removed by an X-ray scanner and a micro-metal inspection machine.

7:Piano Wire Sorting & Magnet

G. Once again, the piano line sorting machine checks cracked beans remained and removes them. Plus, any remaining metallic foreign materials are removed using a strong magnet.

8:Weighing

H. Check the weight of each bag and seal it.

03 Hand-picked service

(For peanuts and other kinds of nuts)

Our hand-picked service involves the nuts being transferred to our own original plastic box and our skilled staff visually inspect each piece of nut and remove any with defects or foreign materials such as shells and stones. The plastic box is easy to clean and we use a different box depending on the materials, enabling us to maintain excellent food hygiene and avoid food contamination.